- Sitemap

- |

- Download

- |

- Blog

- |

- Contact Us

- |

- Inquiry List

About us

For now we developed the professional elevator and escalator parts supplier in China

Our elevator guide rail factory's annual production capacity is 80000 tons of elevator guide rails, also have ISO9001:2008 and CE quality management systerm certification and TES product certification. We fource on the quality of the elevator guide rails, especially on the high speed and heavy elevator guide rail.

Company Introduction

- Professional Elevator guide rail Company in Global

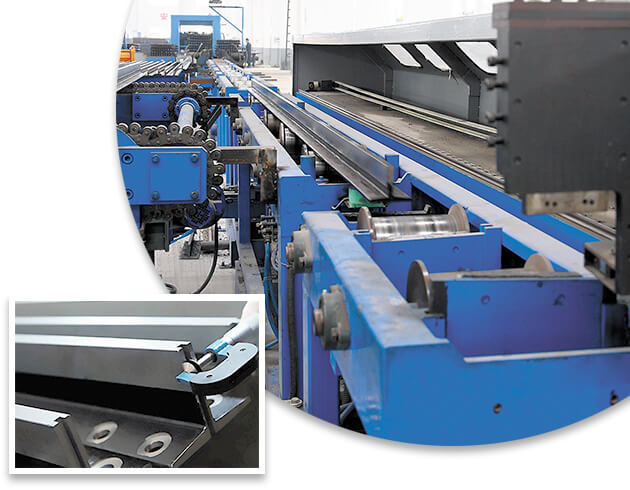

- FIRST company to using fully automatic production line of elevator guide rail in China

- Powerful production ability

- 1000+ employees

Our Vision

Build a famous brand of elevator guide rail in the world

develop with our customers to be the biggest one

Our advantage

Self Research and Development to build core competitive advantage

- Advanced production technology

- The highest standard of quality inspection

- Strong supply chain of raw materials

- Experienced production workers

- ISO&CE certificate

Years Experience

Tons Production Capacity

Rich Experience Employees

Modern and Advance Manufacturing Process, Fully Automated Manufacturing Line, Lean Six Sigma

(Si):0.13%-0.35%;

(Mn):0.35%~0.65% ;

(P)≤0.045%;

(S)≤0.045%。

Increase carbon content in steel, the breaking point and tensile strength will be increased as well but the elongation and resistance to impact will be reduced. Silicon acts as a reducing and deoxidizing agent, Manganese acts as deoxidizing and desulfurizing agent, both improve toughness and strength property of steel. Phosphorus and Sulphurn are toxic agents in the steel, both reduce elongation and toughness property of steel, theirs content is less than 0.045%. The hardness of guide rail will ensure the safety grip gains sufficient friction during the break mechanism.