- Sitemap

- |

- Download

- |

- Blog

- |

- Contact Us

- |

- Inquiry List

JIEFENG GROUP is the Professional escalator step chain supplier in China

because we cooperation with the leading manufacturer in the escalator industry.

Solutions and developments in the areas of noise reduction and low maintenance chain technology are only a few examples of what customers rely on in the escalator industry. Thanks to the high demands on safety and quality JIEFENG escalator and moving walkway chains contribute to the smooth transportation of visitors not only in department stores, subways and airports. London, Madrid, Prague, New York, Shanghai, Peking: JIEFENG products move millions of people every day on escalators and moving walkways across the world.

JIEFENG E&E Escalator Step Chain

Quality, Edurance, Drability, Rliability, Noise reduction

We have been supply escalator step chains for more than 20 years. During this time we have supplied morer than 40 countries escalator maintenance companies, and we got all good feedback from our customers.

Continued Assurance.

All of escalator step chains have 1 year warranty, and we will not provide the low-cost and not guaranteed product, as we all know escalator step chain is safty parts, so it’s very important of continued assurance.

High Standards.

Our product processes ensure that all chain lengths on an escalator machine are manufactured to an overall tolerance of 0.010 inch across 8 Ft, with a quality that enables them to achieve a service life of 20 years

ENDURANCE

JIEFENG Escalator Chain in the public service environment has proven to be extremely wear resistant.

Installation of the JIEFENG Escalator Chain provides lifetime confidence with an extended chain design life.

Years Experience

Cooperation Countries

Cooperation manufacturer

Features:

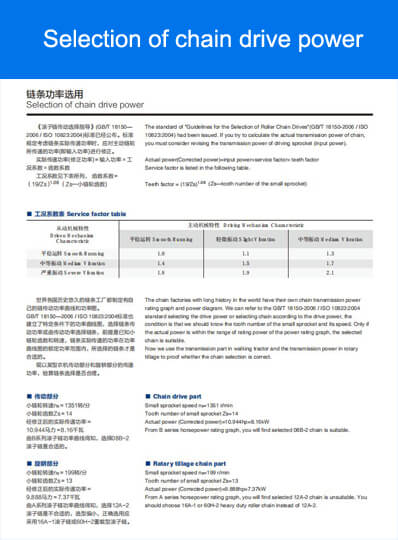

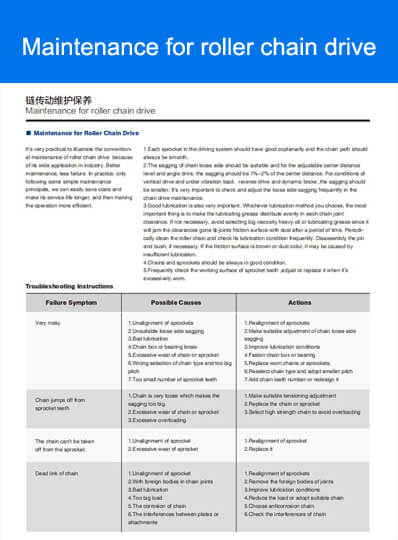

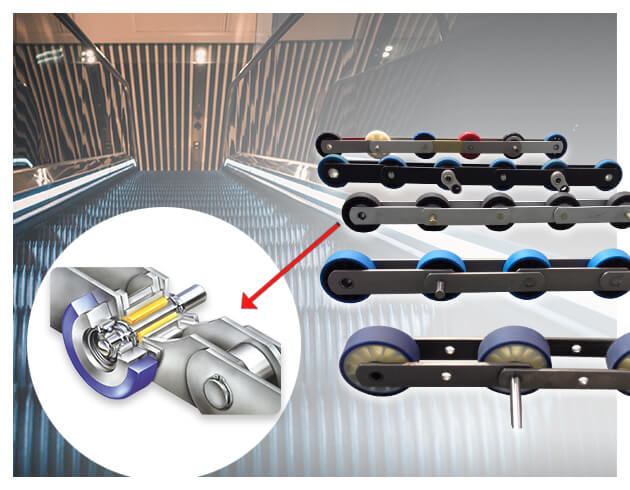

Escalator chain has the characteristics of chain length synchronization accuracy, step distance accuracy and high step distance synchronization accuracy, which meet the requirements of smooth operation. Various special structural designs and unique processing and manufacturing technologies are adopted to meet the requirements of safety, reliability, environmental resistance and long service life.

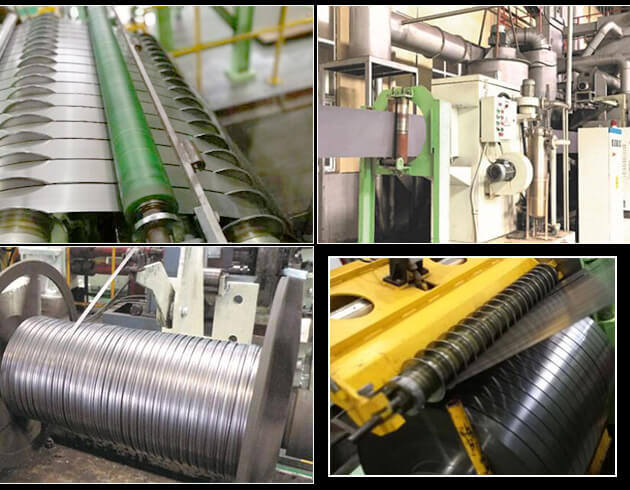

Scale removal on the surface of chain plate raw material

Automatic slitting production line for coiled sheet material

Split shear of chain plate material Continuous processing production line of flat silk Processing of sleeve flat wire

Continuous controllable atmosphere mesh belt furnace

Heat treatment of chain plate, pin shaft, sleeve, roller and other parts

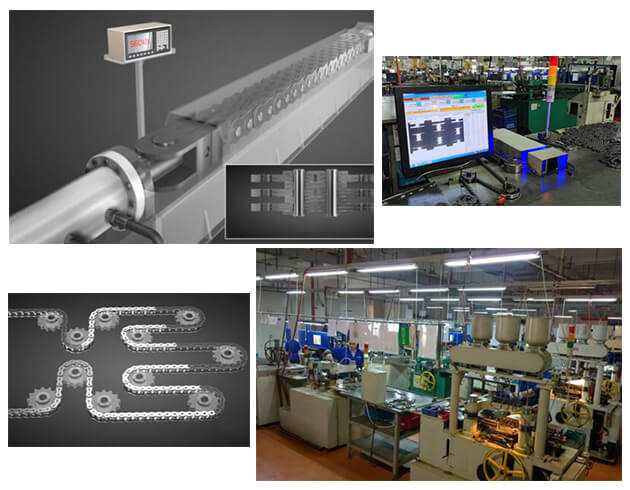

inspectiononline running in/prestretching, online oiling, automatic welding and other advanced process equipment and technologies are widely used to ensure efficient manufacturing of high-quality chain products.

Automatic assembly production line Ensure efficient and

high-quality assembly of chain products

Online detectionFull inspection of chain to ensure product quality Running-in/pretensioning-Reduce the initial wear and

elongation of the chain and improve the fatigue strength of

the chain

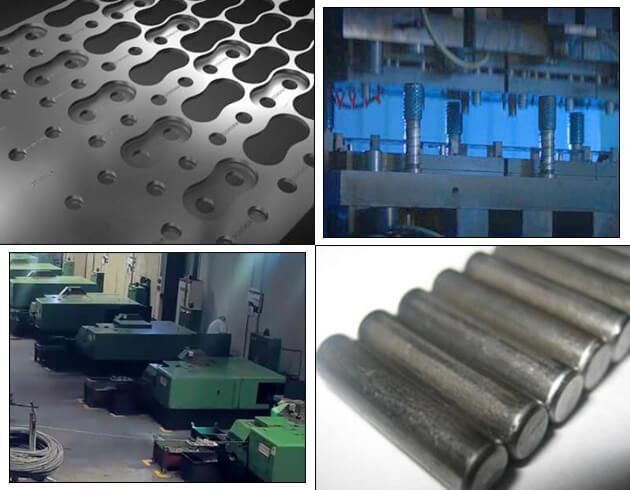

such as high-precision wire cut wire cutting, EDM, coordinate

grinder, vacuum quenching furnace and cryogenic treatment.

Wire cut wire cutting machine tool Achieve precision

machining of mold Vacuum quenching furnace

Mold heat treatment