- Sitemap

- |

- Download

- |

- Blog

- |

- Contact Us

- |

- Inquiry List

Contacts Info.

Technical support

Maintenance for Roller Chain Drive

Views : 641

Author : Cobain

Update time : 2021-03-17 14:25:15

Maintenance for Roller Chain Drive

t’s very practical to illustrate the convention- al maintenance of roller chain drive because of its wide application in industry. Better maintenance, less failure. In practice, only following some simple maintenance principals, we can easily save costs and make its service life longer, and then making the operation more efficient.

t’s very practical to illustrate the convention- al maintenance of roller chain drive because of its wide application in industry. Better maintenance, less failure. In practice, only following some simple maintenance principals, we can easily save costs and make its service life longer, and then making the operation more efficient.

1.Each sprocket in the driving system should have good coplanarity and the chain path should always be smooth.

2.The sagging of chain loose side should be suitable and for the adjustable center distance level and angle drive, the sagging should be 1%~2% of the center distance. For conditions of vertical drive and under vibration load、reverse drive and dynamic brake ,the sagging should be smaller. It’s very important to check and adjust the loose side sagging frequently in the chain drive maintenance.

3.Good lubrication is also very important. Whichever lubrication method you choose, the most important thing is to make the lubricating grease distribute evenly in each chain joint clearance. If not necessary, avoid selecting big viscosity heavy oil or lubricating grease since it will jam the clearances gone to joints friction surface with dust after a period of time. Periodi- cally clean the roller chain and check its lubrication condition frequently. Disassembly the pin and bush, if necessary. If the friction surface is brown or dust color, it may be caused by insufficient lubrication.

4.Chains and sprockets should be always in good condition.

5.Frequently check the working surface of sprocket teeth ,adjust or replace it when it’s excessively worn.

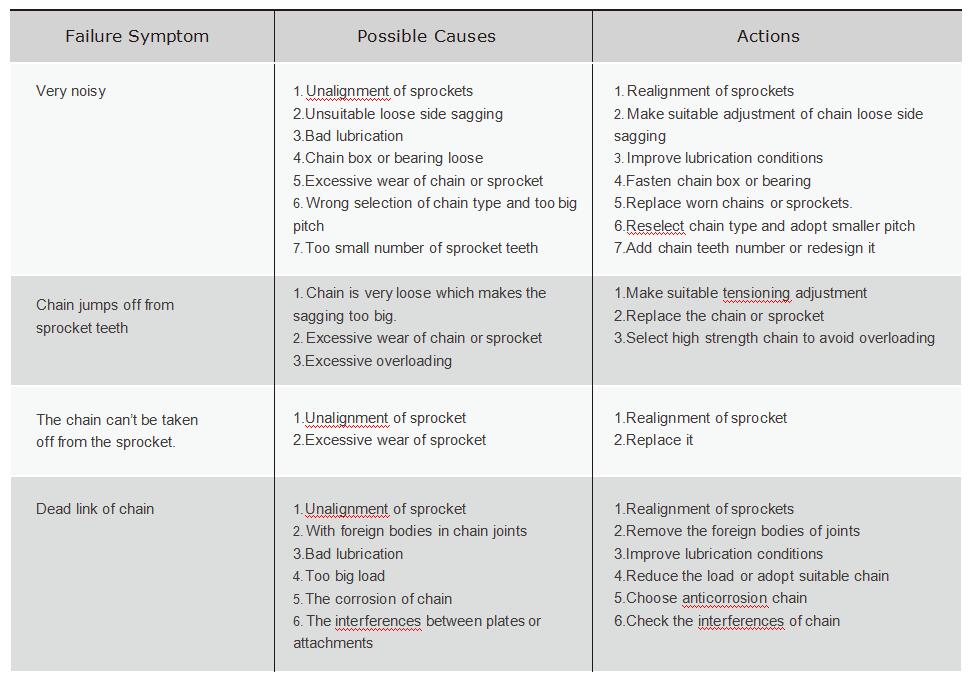

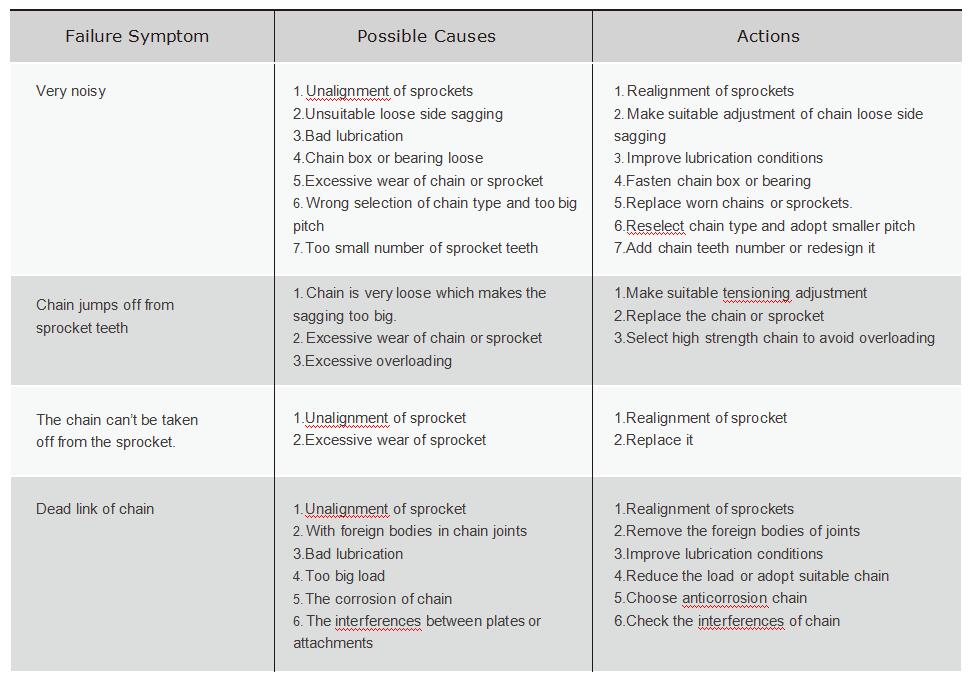

Troubleshooting Instructions

Troubleshooting Instructions

| Failure Symptom | Possible Causes | Actions |

| Roller cracked or deformed |

1. Too big chain pitch or too small number of sprocket teeth 2. Sprocket teeth have foreign bodies. 3.The chain climbs onto sprocket teeth too high. 4.Excessive chain impact load |

1. Select small pitch chain or add sprocket teeth number 2. Remove all the foreign bodies or replace chain 3.Replace the chain and make appropriate tensioning 4.Reduce the impact of chain |

| Pin rotates or plate hole drawn long |

1.Chain overloaded |

1.Eliminate the overloading causes or adopt large specification chain |

| Pin broken or plate broken along the hole connecting line direction |

1.Excessive overloading |

1.Eliminate the overloading causes or adopt large specification or higher strength chain; if sprocket failure symptom found, replace it |

Plates broken |

1.The load above chain dynamic capacity |

1.Selecting big pitch chain or reduce dynamic load |

| Excessive side-wear of plates or sprocket teeth |

1. Sprocket not coplanar or ending beat severely 2. Bad bearing stiffness of sprocket 3.Severe twist of chain |

1.Increase machining and installation precision 2.Increase bearing parts stiffness 3.Replace chain |

| Outer link outside rubbed |

1. Chain not tensioned and jump, then to hit adjacent bodies 2. Chain box deformed or with foreign bodies inside |

1.Make appropriate chain tensioning 2.Eliminate chain box deformation and remove foreign bodies |

| Pin worn or bush bonded with pin |

1. Bad lubrication 2. Chain speed too high or chain overloaded |

1.Supply suitable lubrication system 2.Lower the speed or reduce the load |

| Excessive wear of sprocket |

1. Bad lubrication 2. Inferior material of sprocket and insuffi- cient teeth surface hardness |

1.Improve lubrication conditions 2.Improve sprocket material quality and its teeth surface hardness |

| Locking parts such as spring clip and cotter pin etc. become loose. |

1.Chain wobbling heavily 2.Knock with obstructions 3.Locking parts wrong installed |

1. Make suitable tensioning or consider adding supporting board for guide plate 2. Remove all obstructions 3. Improve the installation quality of locking parts |