- Sitemap

- |

- Download

- |

- Blog

- |

- Contact Us

- |

- Inquiry List

Contacts Info.

Technical support

Selection of lubrication for escalator chain

Views : 738

Author : Cobain

Update time : 2021-03-17 14:45:03

Selection of lubrication

■ Lubrication

Wear is mainly caused by bearing pressure, angle-sliding movements of the pins and rotation of the rollers etc.. Effective lubrica- tion of the chain hinges is utmost important for reducing wear, power loss and noise etc. effectively.

■ Lubrication

Wear is mainly caused by bearing pressure, angle-sliding movements of the pins and rotation of the rollers etc.. Effective lubrica- tion of the chain hinges is utmost important for reducing wear, power loss and noise etc. effectively.

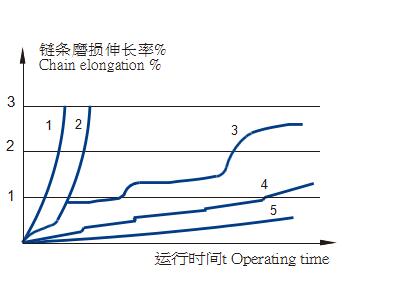

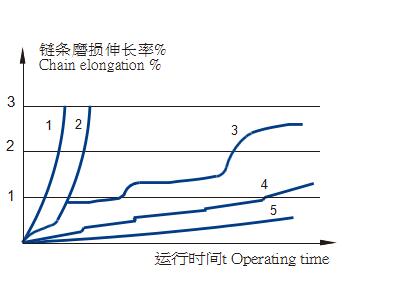

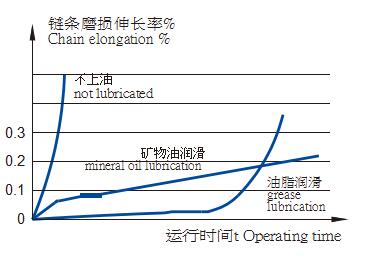

Curve 1:

Without lubrication. Chain would be worn

out and destroyed within a very short 3

time.

Curve 2: 2

Optimum initial lubrication only. High wear

would occur within a short time after the lubricant has been used up. 1

Curve 3:

Manual lubrication. Intermittent dry rub frequently occurs, especially when regular periodical relubrication is not well implemented.

Curve 4:

Incorrect lubrication. Uneven chain wear results from incorrect lubrication.

Curve 5:

Correct lubrication. The right lubrication is the utmost important to obtain a optimum service life.

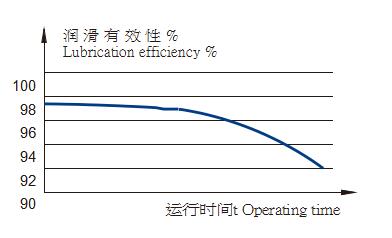

■ ■ Lubrication and ef ficiency

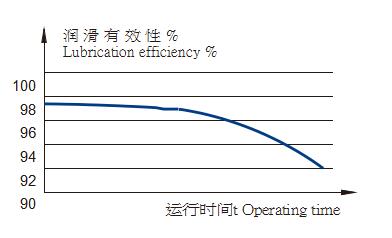

Relubrication shall be done before discoloration of the rub surface which indicates the lubrication failure of the former lubrication.The specific lubrication intervals shall be determined by tests based on specific conditions and running conditions.

The right graph shows the efficiency of lubrication decrease with operating time.

■ ■ Lubricant

■ ■ Lubrication and ef ficiency

Relubrication shall be done before discoloration of the rub surface which indicates the lubrication failure of the former lubrication.The specific lubrication intervals shall be determined by tests based on specific conditions and running conditions.

The right graph shows the efficiency of lubrication decrease with operating time.

■ ■ Lubricant

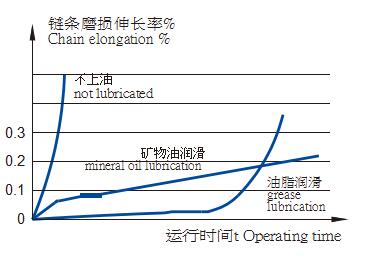

First of all, the selection of an appropriate

lubricant depends on the type of lubrica- tion.

Just as the right diagram shows, low viscosity mineral oils are particularly suitable for chain drives.

Just as the right diagram shows, low viscosity mineral oils are particularly suitable for chain drives.

■ 推荐的不同工作温度下的润滑剂应具备的粘度 Recommended viscosit y

| 环境温度 Ambient temperature ℃ | 润滑剂粘度 Viscosit y of lubricant |

| -5℃~+25℃ | N100 (ISO VG 100) |

| +25℃~+45℃ | N150 (ISO VG 150) |

| +45℃~+60℃ | N220 (ISO VG 220) |

For higher temperatures (e.g. furnace chains) or severe operating conditions, mud spattering open-type etc. or

heavy-duty low speed chains, graphite or molybdenum disulfide (MoS2) applied either as additive or spray will improve lubrication performance.

Low-viscosity or the grease products with a drop point of 70°C are also suitable for manual lubrication. Liquidized grease may be sprayed on the chains in special conditions and chains can start running immediately after the evaporation of the volatile carrier substance.

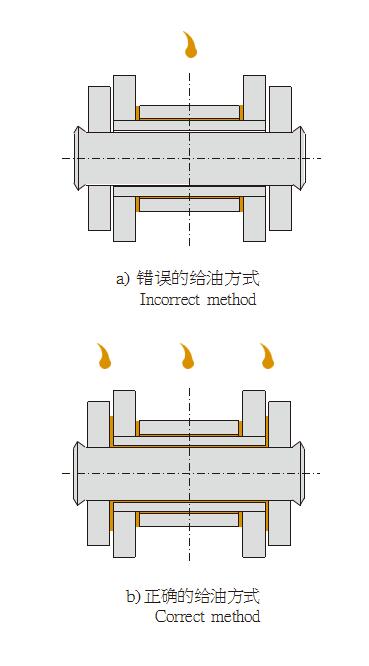

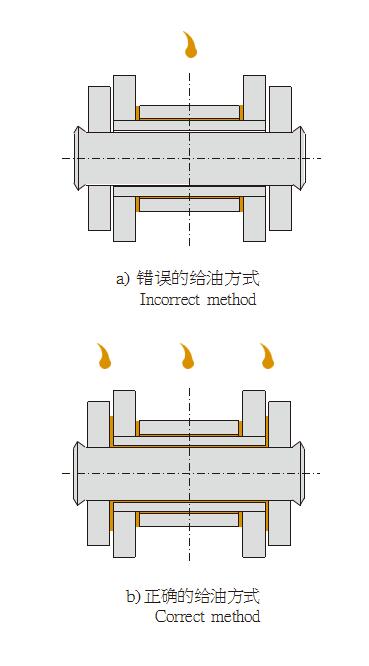

No matter which kind of lubricants and lubrication methods choosed, the most important issue is to ensure the lubricant flow into evenly (between pin and bush, between bush and roller).

■ ■ Selection of lubrication method

■ ■ Selection of lubrication method

Normally, there are five lubrication methods

as below:

1.Manual lubrication

This type of lubrication by means of oil can and brush, which adding lubricant into the gap between outer and inner link plate of chain loose side periodically is not very safe and therefore this type lubrication only suitable for those chains with occasional operation or for those secondary drives and low chain speeds. Sufficient lubrication should take place at least once a day (if possible once every 8 running hours). Lubricant colouration should be avoided as far as possible.

2.Drip lubrication

Drip lubrication by means of wick oilers, needle oilers or drip oilers is only suitable for low bearing pressure drives. Lubricant colouration should be avoided as far as possible.

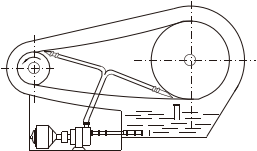

3.Oil bath lubrication (submerged lubrication)

There is just enough oil in a proper chain box for preventing the worn and elongated chain knocking against the casing wall to allow the chain plates to submerge into the bath up to the rollers or the bushings respectively. But immersion should not be too deep or too shallow .Too shallow immersion lubrication is not reliable. Too deep immersion may cause the oil to heat up and lead to untimely oxidation of the oil.

4.Oil-ring lubrication (splash lubrication)

With this type of lubrication, the chain operates above oil level. A disk submerg- ing into the lower oil level, the depth is about 12.7mm-25.4mm, Peripheral velocity between min. 3m/s and max.

40m/s, normally not bigger than 12.5m/s, centrifuges oil against the casing walls from where it continuously runs down onto the chain via drip rails. The disk should be mounted on both sides of sprocket when the chain width above 127mm.

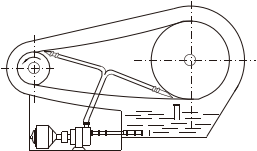

5.Force feed lubrication (pressure lubrication)

This type of lubrication is suitable for high-speed and heavy-duty type drives.

Force feed lubrication is carried out to realize the circulating cooling of chains by means of oil pump and oil feeding

pipe .The spray nozzles should be situated near the gearing places of chain and sprocket, and the nozzle number should be one more than the chain strands number to make them aim at the gap of each row link plate.