- Sitemap

- |

- Download

- |

- Blog

- |

- Contact Us

- |

- Inquiry List

Categories

Contacts Info.

Escalator Step Chain

RAC Escalator Step Chain with Shaft FOB9814CE

Item No.: RAC

QUALITY RAC STEP CHAIN FOR OTIS ESCALATOR FOB9814CE

Description

Shopping Guide

Selection of chain drive power

Maintenance for roller chain drive

PRODUCT CENTER

JIEFENG GROUP, founded in 2007, is a global elevator and escalator parts manufacturer.We have our elevator guide rail factory, direct holding escalator step chain factory, own elevator, and escalator parts company.

In the Product Center, a wide range of JIEFENG's product lines can be found: Elevator machined guide rail, Elevator hollow guide rail, Elevator cold drawn guide rail, Elevator guide rail fish plate, Escalator step chain, Traction machine, elevator, and escalator spare parts, etc.

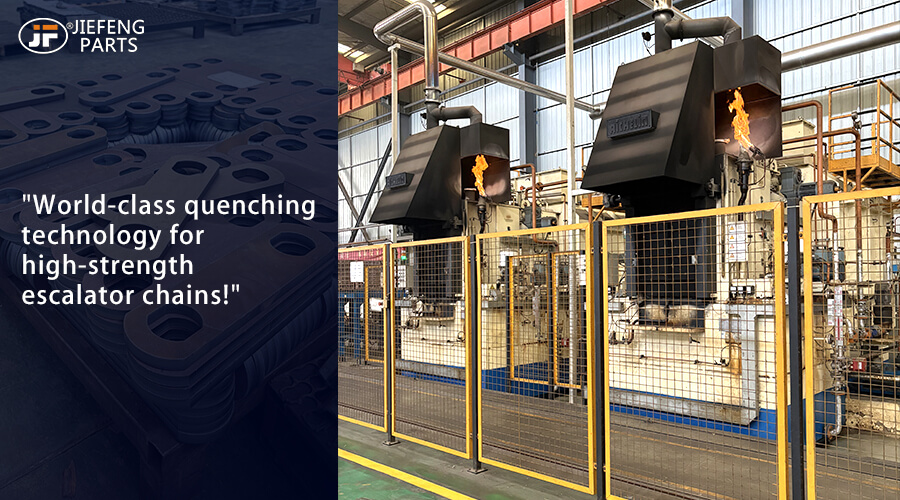

The RAC Step Chain is heavy duty type its brake force is 288KN.

RAC Step Chain Size

Part Number: FOB9814CE

Size:Pitch=135.466mm Outside Roller=140*28mm;

Chain Plate=70*6mm+76*6mm Pin Diameter=30mmSteel Roller Dia=40mm

Material: Steel+ Metal Roller;

Lead time: 35~45 Days after payment

Escalator step chains |

Escalator drive chains |

Escalator step chains

● Escalator step chain is used in escalator and moving sidewalk systems to transmit power and transport passengers. It is widely used in escalator facilities such as the subway, high-speed rail, airports, shopping malls, and supermarkets.

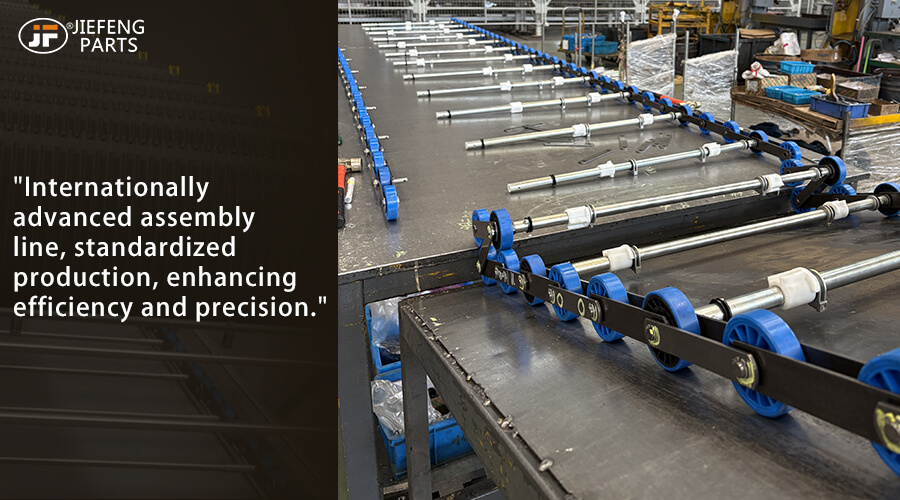

● Advanced processing and manufacturing technologies such as special structural design and new chain plate blanking are adopted, which have the characteristics of high step distance accuracy, step distance synchronization accuracy, and chain length synchronization accuracy, and meet the requirements of stable operation, safety, reliability, environmental resistance and long service life.

● Fully cover the ladder chain products used in the escalator industry, and independently develop high-end products with unique structures such as oil cup type and self-lubricating type. Product pitch range: 67~136mm, breaking load range: 60~1100kN.

The escalator step chain is a very important part of the escalator or moving walk.

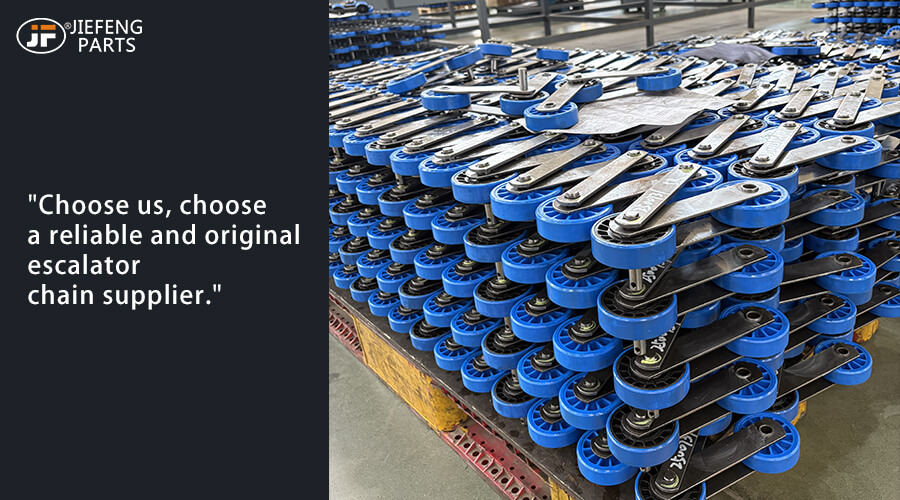

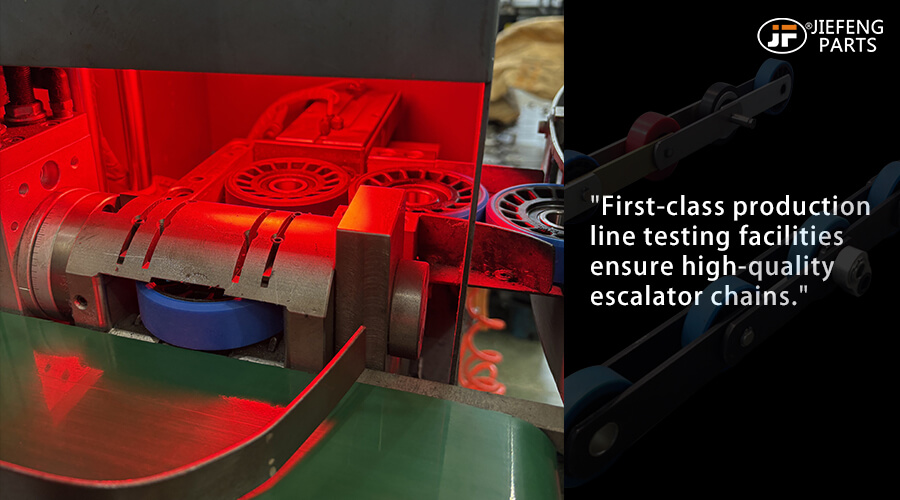

All of our escalator step chains have the best quality on the market, and all of our suppliers are OEMs for known escalator factories.

So we can provide you with a 100% original escalator step chain.

We have all kinds of escalator step chains, and the detailed shopping guide is as follows;

1, We have to check the brand of the escalator;

2, Then we must check the type of escalator, like 506, 506NCE, 606NCT, 606NPT, 510NPE, 513, R, RB, 9300, 9300-10, 9300-11, 9300AE, 9500, RSE, 9700, 13KV-C, 10DH-C, 13DH-C,13KV-SF, 13RI-A, 13RI-A-TS, 20RI-A, 20RI-A-TS, 25RI-A, RTV, RTK, 16HDV, 20HDV-C, 22HDV-C, FT722, FT822, FS880, ECO, Orinoco, Avante, FT840, K25S, K26S, K6, K10, K15 etc;

3, Then we can check all the datasheet of the escalator step chain, like pitch distance, the diameter of the roller, the diameter of the pin, etc;

An escalator chain is used in the escalator and moving sidewalk system to transfer power and transport passengers. Escalator chains are widely used in subways, high-speed rail, airports, high-end shopping malls, supermarkets, and other places along with escalators and other facilities, including various drive chains, escalator step chains, and automatic sidewalk pedal chains.

Commercial type for commercial use

Free of lubrication type

Public transport type for public transport

Moving walk pallet chains

All of our escalator step chains have the best quality on the market, and all of our suppliers are OEMs for known escalator factories.

So we can provide you with a 100% original escalator step chain.

We have all kinds of escalator step chains, and the detailed shopping guide is as follows;

1, We have to check the brand of the escalator;

2, Then we must check the type of escalator, like 506, 506NCE, 606NCT, 606NPT, 510NPE, 513, R, RB, 9300, 9300-10, 9300-11, 9300AE, 9500, RSE, 9700, 13KV-C, 10DH-C, 13DH-C,13KV-SF, 13RI-A, 13RI-A-TS, 20RI-A, 20RI-A-TS, 25RI-A, RTV, RTK, 16HDV, 20HDV-C, 22HDV-C, FT722, FT822, FS880, ECO, Orinoco, Avante, FT840, K25S, K26S, K6, K10, K15 etc;

3, Then we can check all the datasheet of the escalator step chain, like pitch distance, the diameter of the roller, the diameter of the pin, etc;

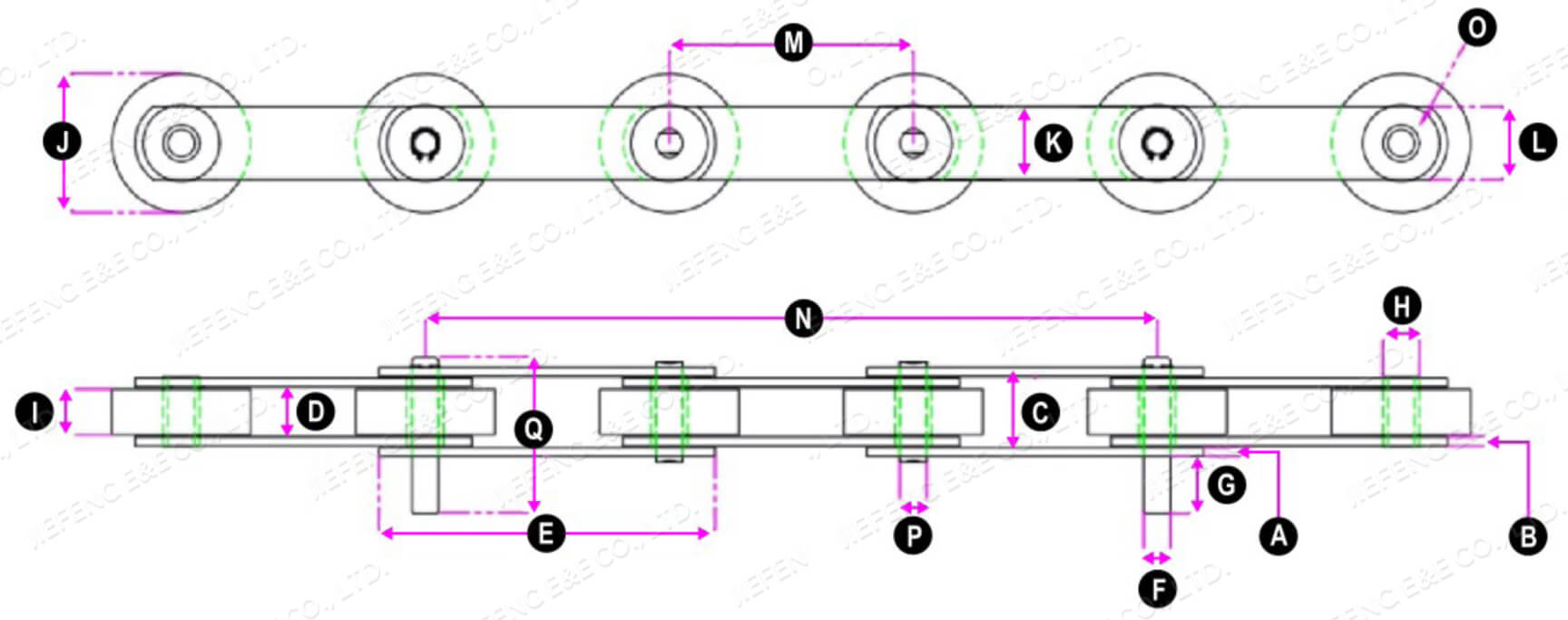

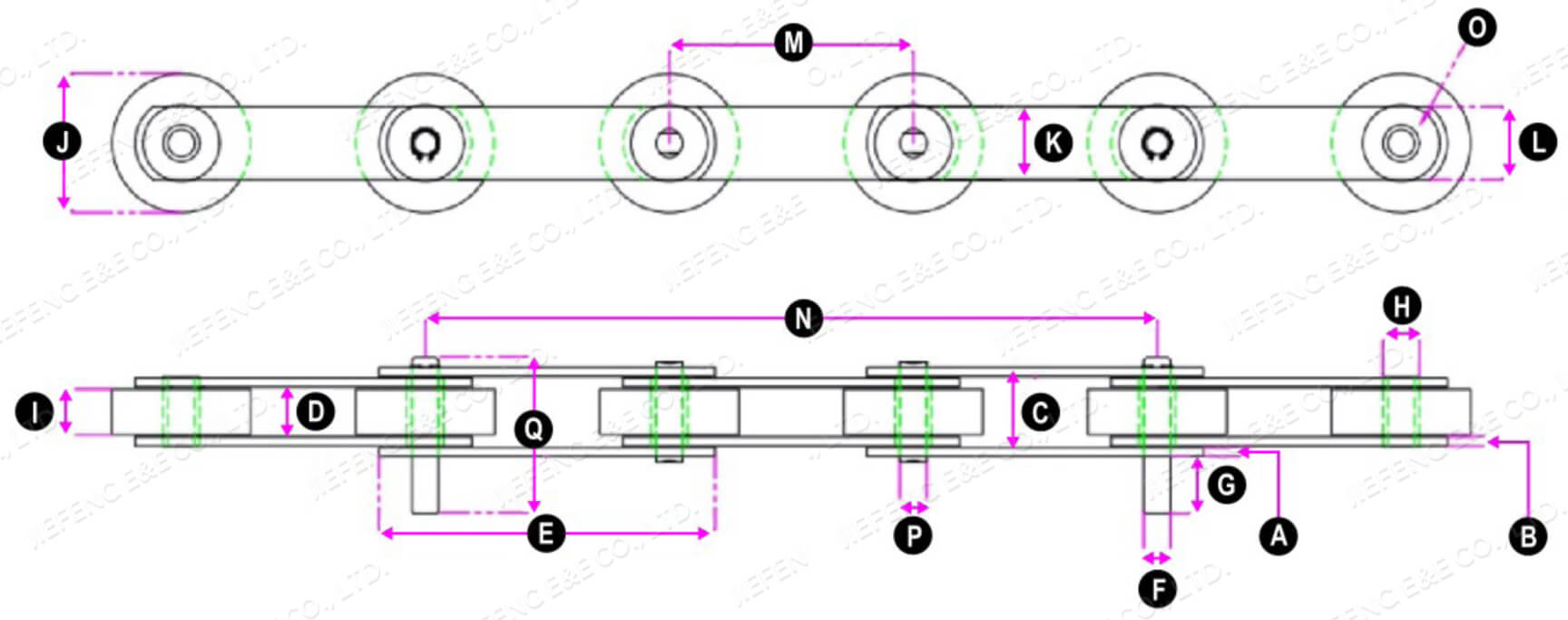

| A the thickness of the outer link plate | I the width of the chain roller |

| B Thickness of inner link plate | J Diameter of step chain roller |

| C Distance between outer link plates | K Height/width of the outer link |

| D Distance between inner link plats | L Height/width of inner link |

| E Length of the link plate | M Pitch between pins |

| F Diameter of step connecting pin | N Pitch between step connecting pins |

| G Length of step connecting pin | O Roller bearing information |

| H Diameter of the chain pin | P Roller pin diameter |

| Q Total pin length |

An escalator chain is used in the escalator and moving sidewalk system to transfer power and transport passengers. Escalator chains are widely used in subways, high-speed rail, airports, high-end shopping malls, supermarkets, and other places along with escalators and other facilities, including various drive chains, escalator step chains, and automatic sidewalk pedal chains.

Commercial type for commercial use

| 节距 Pitch |

梯级距 Step distance |

抗拉强度 Tensile strength |

| 133.33 | 400.0 | 75 kN~260 kN |

| 135.46 | 406.4 | 70 kN~155 kN |

| 68.40 | 410.4 | 98 kN~161.4 kN |

| 135.00 | 405.0 | 130 kN~205 kN |

| 136.00 | 410.4 | 80 kN~160 kN |

Free of lubrication type

| 节距 Pitch |

梯级距 Step distance |

抗拉强度 Tensile strength |

| 133.33 | 400.0 | 88 kN~380 kN |

| 135.46 | 406.4 | 123 kN~160 kN |

| 101.15 | 404.6 | 150 kN~300 kN |

| 100.00 | 400.0 | 240 kN~320 kN |

Public transport type for public transport

| 节距 Pitch |

梯级距 Step distance |

抗拉强度 Tensile strength |

| 133.33 | 400.0 | 130 kN~520 kN |

| 135.46 | 406.4 | 150 kN~400 kN |

| 101.15 | 404.6 | 120 kN~450 kN |

| 102.60 | 410.4 | 170 kN~360 kN |

Moving walk pallet chains

| 节距 Pitch |

梯级距 Step distance |

抗拉强度 Tensile strength |

| 133.33 | 400.0 | 90 kN~180 kN |

| 135.46 | 406.4 | 127 kN~150 kN |

| 120.00 | 360.0 | 105 kN~120 kN |

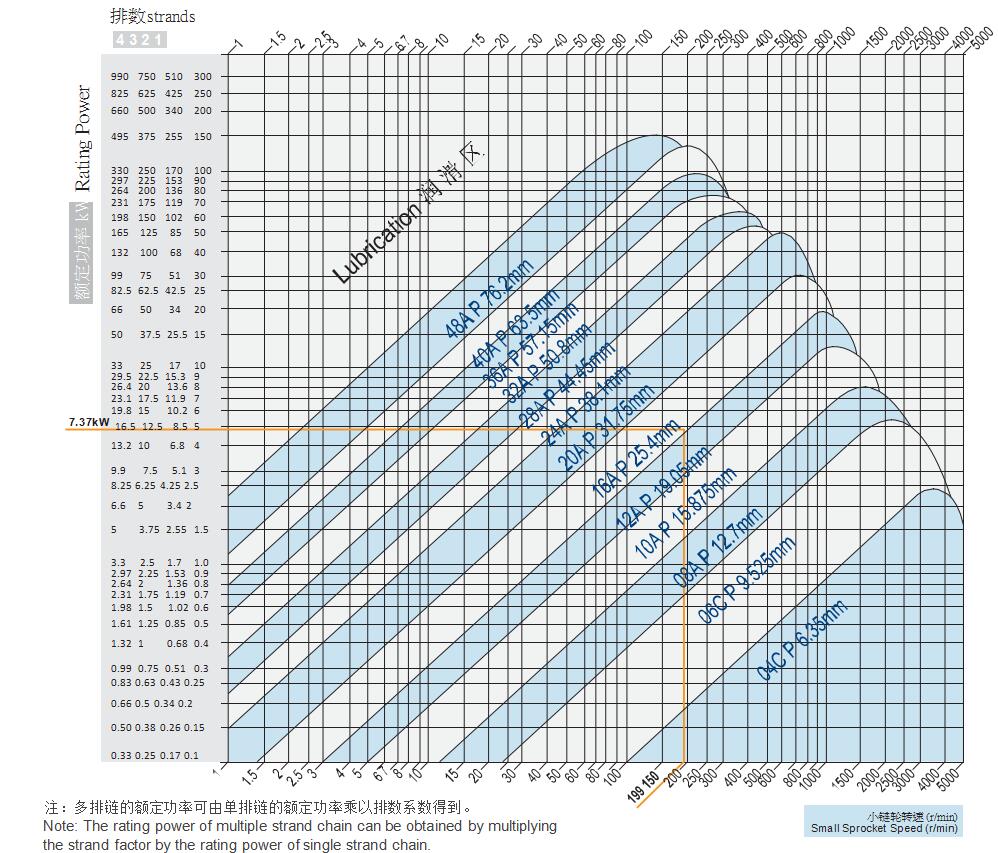

Selection of chain drive power

The standard of "Guidelines for the Selection of Roller Chain Drives"(GB/T 18150-2006 / ISO 10823:2004) has been issued. If you try to calculate the actual transmission power of the chain, you must consider revising the transmission power of the driving sprocket (input power).

Actual power(Corrected power)=input power × service factor × teeth factor Service factor is listed in the following table.

Teeth factor = (19/Zs)1.08 (Zs—tooth number of the small sprocket)

■工况系数表 Service factor table

■工况系数表 Service factor table

| 从动机械特性 Driven Mechanism Characteristic |

主动机械特性 Driving Mechanism Characteristic | ||

| 平稳运转 Smooth Running |

轻微振动 Slight Vibration |

中等振动 Medium Vibration |

|

| 平稳运转 Smooth Running | 1.0 | 1.1 | 1.3 |

| 中等振动 Medium Vibration | 1.4 | 1.5 | 1.7 |

| 严重振动 Severe Vibration | 1.8 | 1.9 | 2.1 |

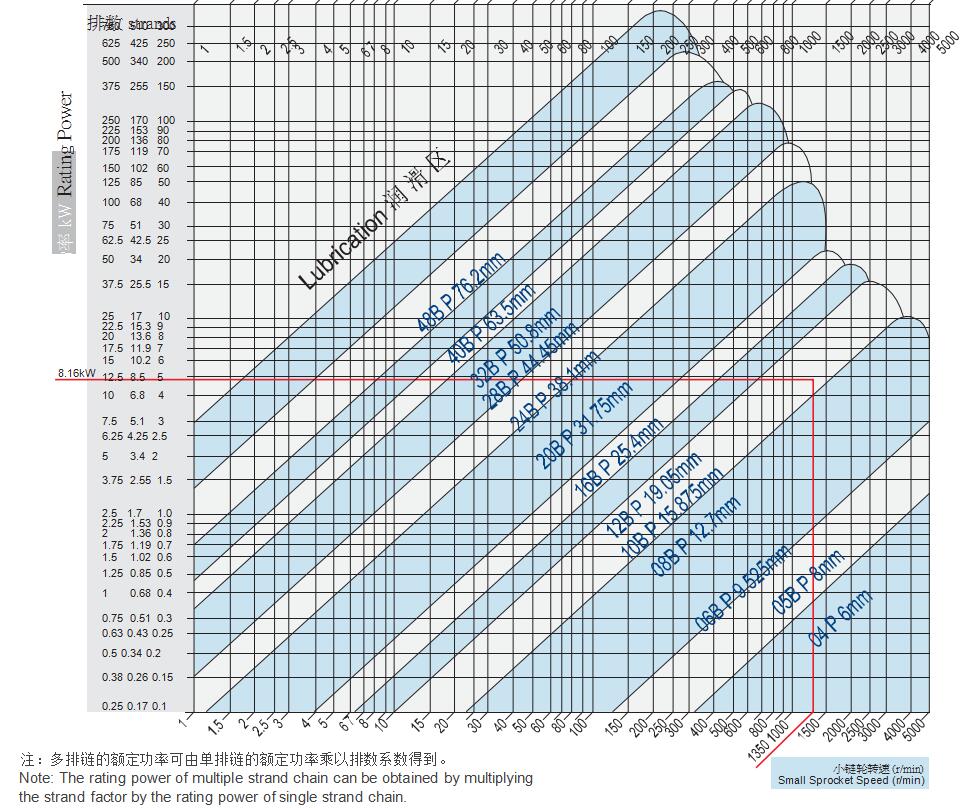

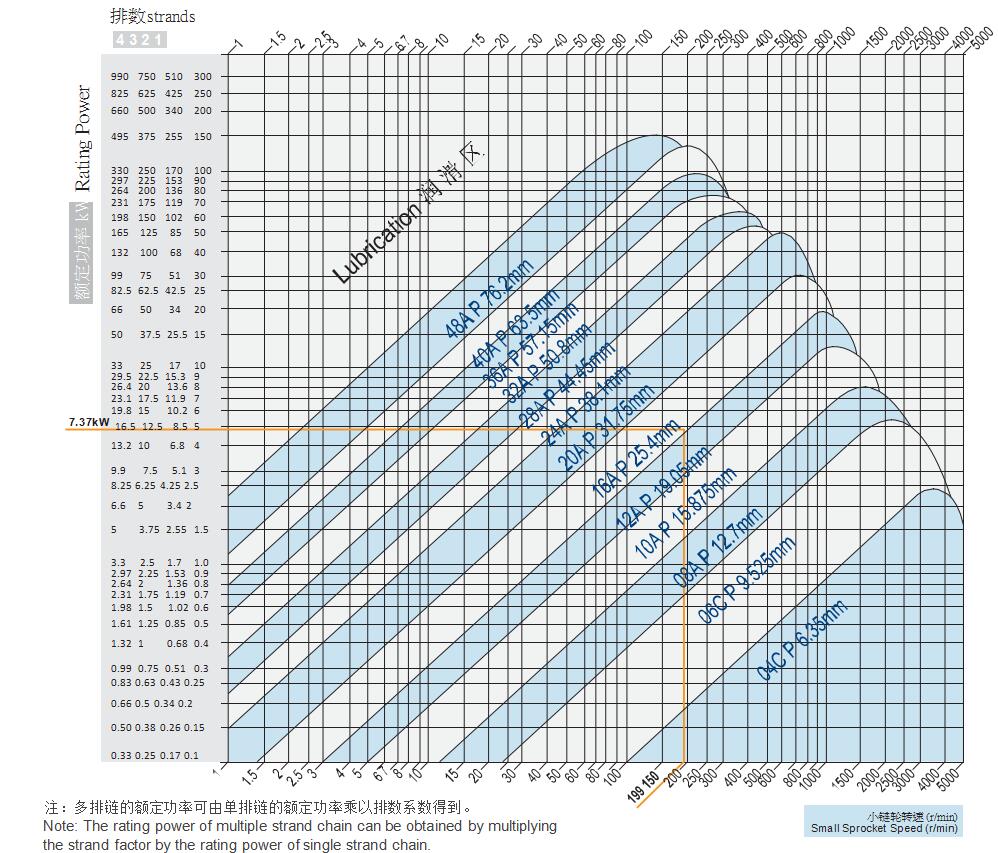

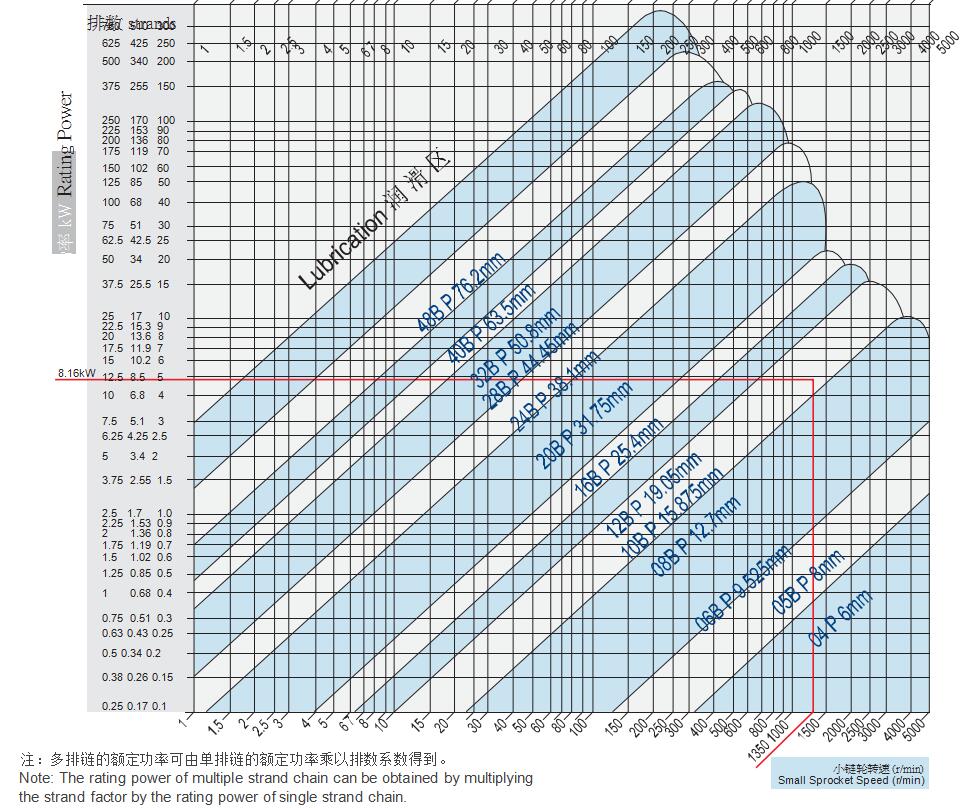

Chain factories with a long history in the world have their chain transmission power rating graph and power diagram. We can refer to the GB/T 18150-2006 / ISO 10823:2004 standard selecting the drive power or selecting the chain according to the drive power, the condition is that we should know the tooth number of the small sprocket and its speed. Only if the actual power is within the range of rating power of the power rating graph, the selected chain is suitable.

Now we use the transmission part in the walking tractor and the transmission power in rotary tillage to prove whether the chain selection is correct.

■ Chain drive part

■ Chain drive part

Small sprocket speed ns=1351 r/min Tooth number of small sprocket Zs=14

Actual power (Corrected power)=10.944hp=8.16kW

From the B series horsepower rating graph, you will find that the selected 08B-2 chain is suitable.

■ Ratar y tillage chain part

■ Ratar y tillage chain part

Small sprocket speed ns=199 r/min Tooth number of small sprocket Zs=13

Actual power (Corrected power)=9.888hp=7.37kW

From the A series horsepower rating graph, you will find selected 12A-2 chain is unsuitable. You should choose a 16A-1 or 60H-2 heavy-duty roller chain instead of 12A-2.

■ The main characteristics of this power graph are as follows:

■ The main characteristics of this power graph are as follows:

For drive Zs=19

Chain length: 120 pitches Transmission ratio: 1:3 to 3:1 Service life of chain: 15000 hours

■ The main characteristics of this power graph are as follows:

| 排 数 Number of strands | 1 | 2 | 3 | 4 | 5 | 6 |

| 系 数 Factor | 1.0 | 1.7 | 2.5 | 3.3 | 4.1 | 4.9 |

功率曲线图(B系列滚子链)

Power rating graph ( B series roller chain )■ The main characteristics of this power graph are as follows:

For drive Zs=19

Chain length: 120 pitches Transmission ratio: 1 : 3 to 3: 1

Service life of chain: 15000 hours

Service life of chain: 15000 hours

■ 排数系数表 Strand factor table

| 排 数 Number of strands | 1 | 2 | 3 | 4 | 5 | 6 |

| 系 数 Factor | 1.0 | 1.7 | 2.5 | 3.3 | 4.1 | 4.9 |

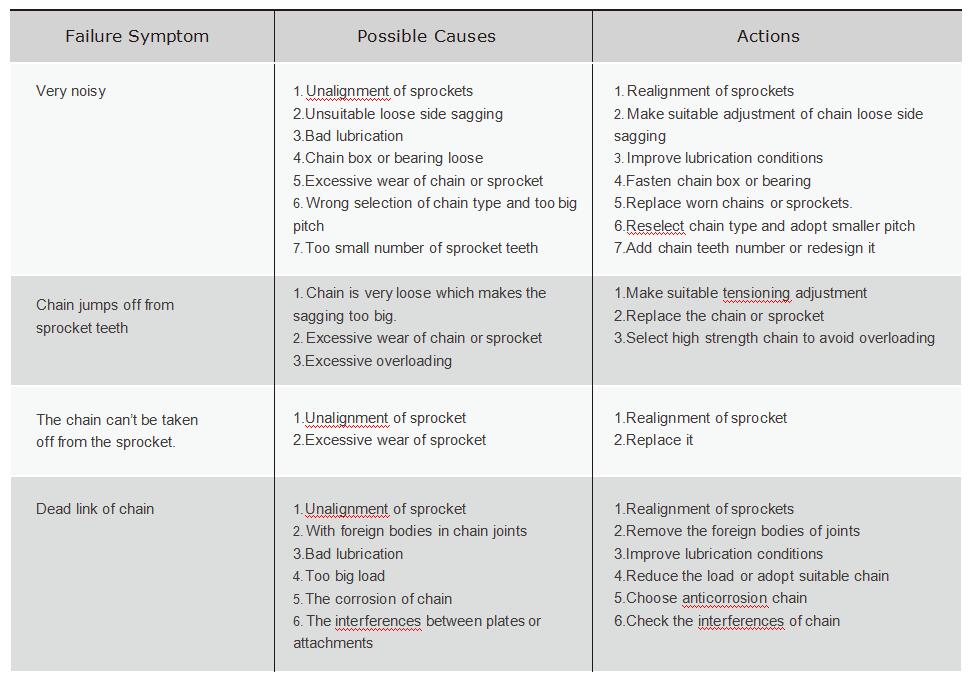

Maintenance for Roller Chain Drive

It’s very practical to illustrate the convention- al maintenance of roller chain drive because of its wide application in industry. Better maintenance, less failure. In practice, only by following some simple maintenance principles, we can easily save costs make its service life longer, and then make the operation more efficient.

It’s very practical to illustrate the convention- al maintenance of roller chain drive because of its wide application in industry. Better maintenance, less failure. In practice, only by following some simple maintenance principles, we can easily save costs make its service life longer, and then make the operation more efficient.

1. Each sprocket in the driving system should have good coplanarity and the chain path should always be smooth.

2. The sagging of the chain loose side should be suitable and for the adjustable center distance level and angle drive, the sagging should be 1%~2% of the center distance. For conditions of vertical drive and under vibration load、reverse drive and dynamic brake, the sagging should be smaller. It’s very important to check and adjust the loose side sagging frequently in the chain drive maintenance.

3. Good lubrication is also very important. Whichever lubrication method you choose, the most important thing is to make the lubricating grease distribute evenly in each chain joint clearance. If not necessary, avoid selecting big viscosity heavy oil or lubricating grease since it will jam the clearances gone to joints friction surface with dust after some time. Periodically clean the roller chain and check its lubrication condition frequently. Disassemble the pin and bush, if necessary. If the friction surface is brown or dust color, it may be caused by insufficient lubrication.

4. Chains and sprockets should be always in good condition.

5. Frequently check the working surface of sprocket teeth, and adjust or replace it when it’s excessively worn.

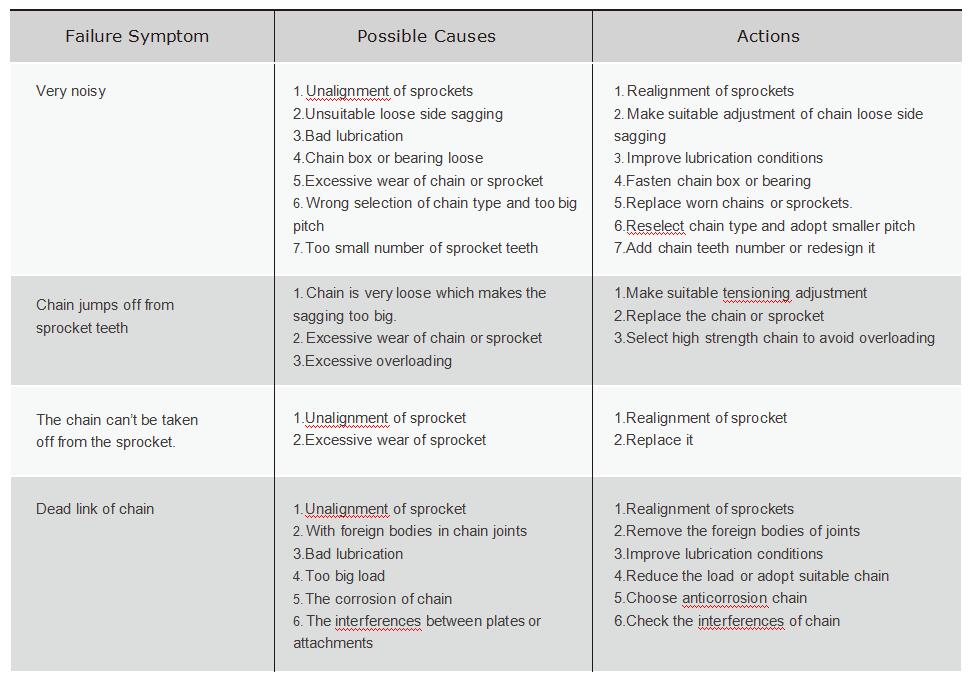

Troubleshooting Instructions

Troubleshooting Instructions

| Failure Symptom | Possible Causes | Actions |

| Roller cracked or deformed |

1. Too big chain pitch or too small number of sprocket teeth 2. Sprocket teeth have foreign bodies. 3. The chain climbs onto sprocket teeth too high. 4. Excessive chain impact load |

1. Select a small pitch chain or add sprocket teeth number 2. Remove all the foreign bodies or replace chain 3. Replace the chain and make appropriate tensioning 4. Reduce the impact of chain |

| Pin rotates or plate hole is drawn long |

1. Chain overloaded |

1. Eliminate the overloading causes or adopt a large specification chain |

| Pin broken or plate broken along the hole connecting line direction |

1. Excessive overloading |

1. Eliminate the overloading causes or adopt a large specification or higher strength chain; if a sprocket failure symptom is found, replace it |

Plates broken |

1. The load above chain dynamic capacity |

1. Selecting a big pitch chain or reducing dynamic load |

| Excessive side wear of plates or sprocket teeth |

1. Sprocket not coplanar or ending beat severely 2. Bad bearing stiffness of sprocket 3.Severe twist of chain |

1. Increase machining and installation precision 2. Increase bearing parts stiffness 3. Replace chain |

| The outer link outside rubbed |

1. Chain not tensioned and jump, then hit adjacent bodies 2. Chain box deformed or with foreign bodies inside |

1. Make appropriate chain tensioning 2. Eliminate chain box deformation and remove foreign bodies |

| Pin worn or bush bonded with pin |

1. Bad lubrication 2. Chain speed too high or chain overloaded |

1. Supply a suitable lubrication system 2. Lower the speed or reduce the load |

| Excessive wear of sprocket |

1. Bad lubrication 2. Inferior material of sprocket and insuffi- cient teeth surface hardness |

1. Improve lubrication conditions 2. Improve sprocket material quality and its teeth surface hardness |

| Locking parts such as spring clip and cotter pin etc. become loose. |

1. Chain wobbling heavily 2. Knock with obstructions 3. Locking parts wrong installed |

1. Make suitable tensioning or consider adding a supporting board for the guide plate 2. Remove all obstructions 3. Improve the installation quality of locking parts |